TURNKEY AUTOMATED SYSTEMS

System Software Products

The SMART Product line from Inovision is designed to be just that - SMART. We have analyzed the needs of our customers and have developed solutions that are easier to use, more durable, or faster than our competitor products.

SMARTTrack® Industrial Internet of Things

SMARTTrack® Industrial Internet of Things (IIoT) and Industry 4.0 are terms used to describe the latest trends in manufacturing technology, but are areas that we worked in since we started. We are adding smart devices, RFID, blue tooth readers, barcode, QR scanners, and Wi-Fi adapters to existing equipment, collecting data, analyzing it, and reporting into existing plant information systems. There are many ways to add "intelligence" to many of your existing systems, without spending a lot of money.

- Retrofits existing equipment with sensors and smart modules without major overhauls.

- Continuously collects and analyzes performance data to support informed decisions.

- Adds intelligence to legacy systems with minimal investment and downtime.

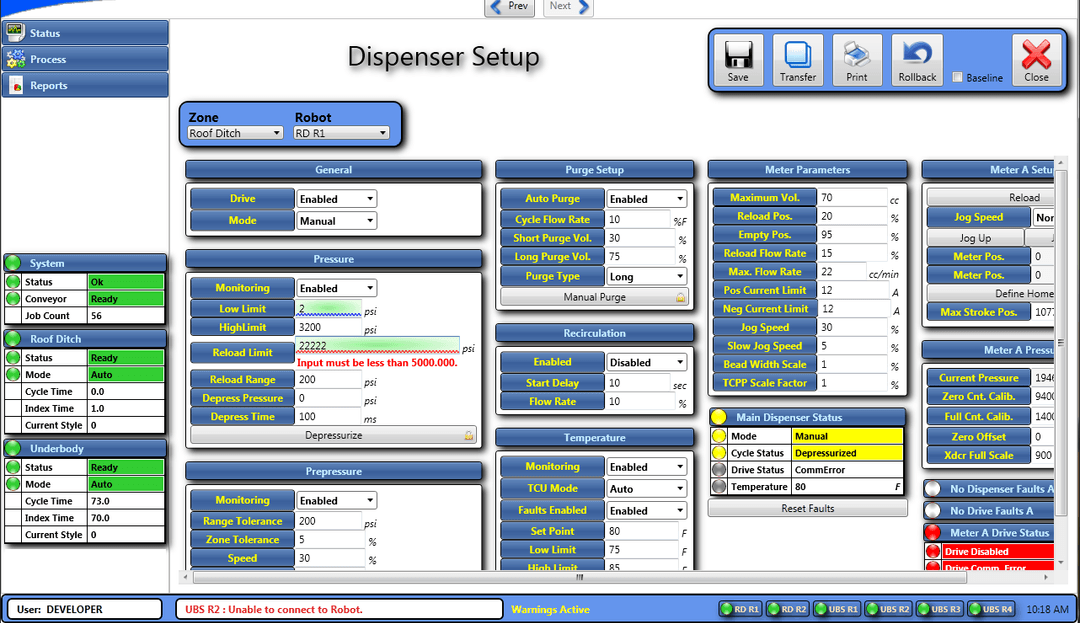

SMARTUI

HMI and GUIs that are intuitive and easy to use. Using a WPF interface we can easily create a User Interface for your automation system that has useful data and information at your operators finger tips. We can retrofit your old Windows 95 systems that are obsolete and no longer supported, or provide a flexible alternative to your current Wonderware, Visual Basic, .Net, and PaintWorks operator stations.

- POWERPAINT is designed in the Windows Presentation Foundation (WPF) is a user interface development environment. This advanced environment provides access to more advanced visuals, such as interfaces that incorporate documents, media, two- and three-dimensional graphics, animations, Web-like characteristics, and more.

- Storing data in objects allows for intuitive data display that you can move and "pop-up" as needed. Instead of having a heavy-menu-driven, we design a multi-window experience, to allow users to focus on only the important information they need at one time.

- We have implemented the PC Based SMARTUI system in large automotive manufacturers and general industrial plants, each with their own security protocols for PC Based Applications.

MotionView

MotionView was built from the ground up to simplify big data analysis, reduce storage costs, and maximize shop floor visibility. Designed to support stakeholders at all levels, MotionView empowers them with tools to improve production and increase revenue by leveraging data from robots, PLCs, and sensors in real-time.

- MotionView brings factory data to life with both 2D and 3D visualizations. The 2D dashboard allows for easy monitoring of production metrics, alarm counts, and downtime, while the 3D production view offers a revolutionary, real-world perspective of the shop floor, making data more actionable and interactive.

- MotionView analyzes data in real-time, streaming it to the dashboard for immediate visibility. It also records data locally or in the cloud for playback, similar to a DVR, allowing users to review past production data for detailed analysis and troubleshooting.

- MotionView connects directly to robot controllers, PLCs, and other industrial equipment using Ethernet/IP and other protocols. Powered by TimeScaleDB on PostgreSQL, it ensures high reliability and exceptional performance in data storage and analysis, with industry-leading data compression and query speed.

SMARTDisplay

SMARTDisplay is a robust and customizable solution designed to enhance operator efficiency by providing visual and audible cues. Connected to a PLC, it displays part and vehicle information while supporting custom images and audio to guide operators through tasks. With a 24/7 rated display and Ethernet connectivity, SMARTDisplay ensures seamless integration into production environments and can adapt to changing requirements.

- The SMARTDisplay is designed for continuous, around-the-clock operation, ensuring durability and reliability in demanding manufacturing environments. It delivers real-time data to operators, helping them make informed decisions without interruptions.

- SMARTDisplay allows for the easy integration of custom images and audio that are triggered based on part attributes sent from the PLC. This flexibility ensures that the display can be modified as production requirements change, helping operators stay aligned with evolving tasks and assembly instructions.

- The page header of SMARTDisplay is dedicated to displaying critical part or vehicle information, ensuring operators have the right details at their fingertips. This feature helps prevent errors and keeps the focus on the current production task.

Ready to improve your process?

Whether you're planning a new system or optimizing an existing one, our team can help you design the right automation solution for your production goals.