TURNKEY AUTOMATED SYSTEMS

Automated Tape & Other Dispense Applications

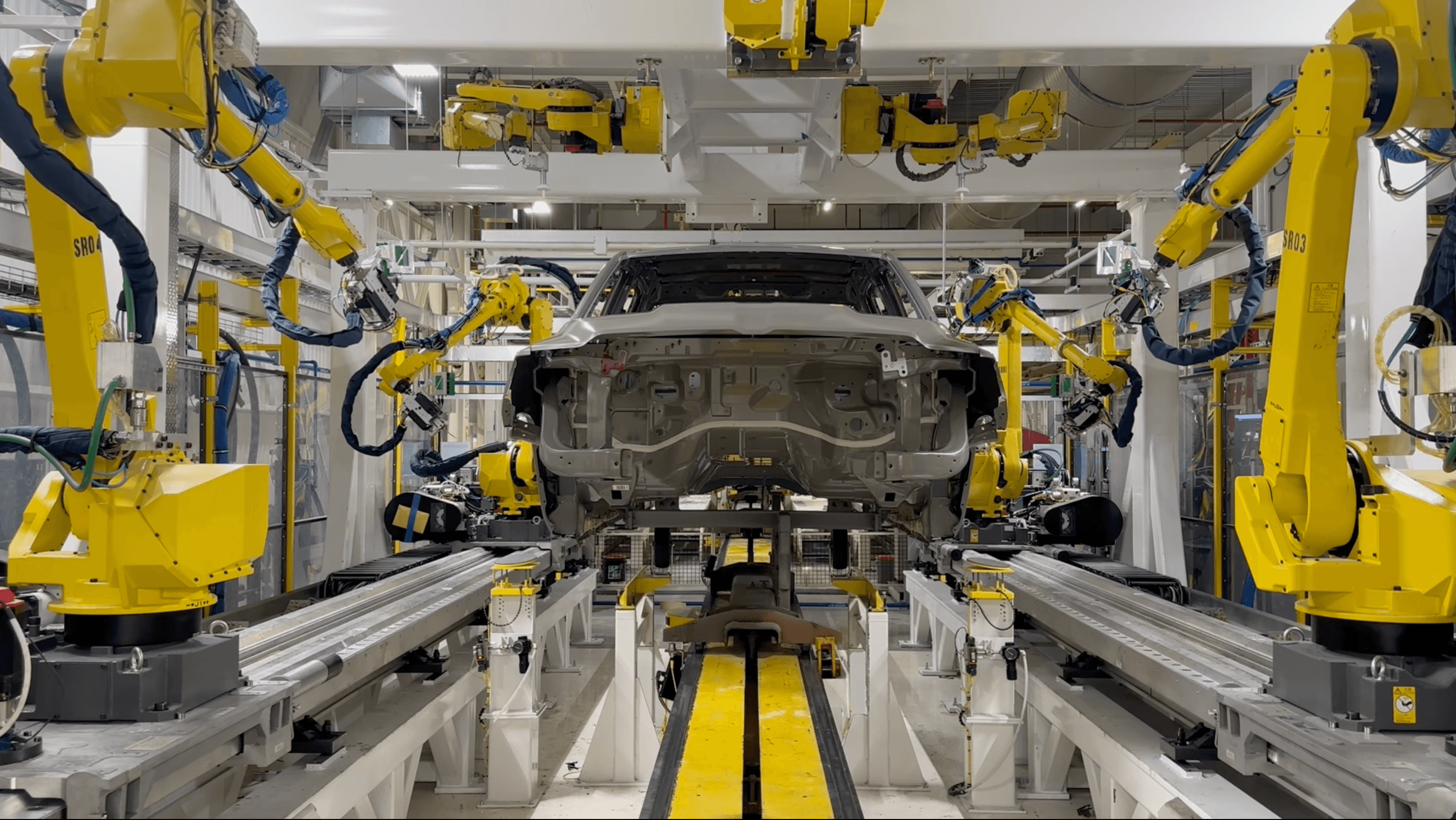

Encore Automation is at the forefront of innovation in Automated Tape Applications. Our cutting-edge automation solutions ensure precise and reliable tape placement, enhancing efficiency, accuracy, and overall product quality. We empower manufacturers to streamline processes, reduce waste, and consistently meet the highest industry standards.

Automated Taping Application

Encore owns a patented end of arm tool for automating the tape dispensing, application, and vision verification. Our applicator heads feature vacuum suction with continuous pressure monitoring to ensure tape presence. The tooling can be configured with multiple customizable heads to accommodate various shapes and sizes. This airtight solution effectively seals drain holes, providing a reliable alternative to traditional plugs and patches. Its innovative design separates the applicator from the dispenser, enabling access to hard-to-reach areas. This solution enhances quality, reduces ergonomic strain from manual application, and lowers material costs.

- Robotic integration enhances precision, flexibility, and efficiency, enabling automated processes for consistent and high-quality application.

- Automated sealing ensures PTED drain holes are properly covered, preventing water intrusion and improving vehicle durability.

- Advanced robotic systems automate the replacement of grommets and plugs, reducing manual labor while ensuring secure and reliable sealing.

Liquid Applied Protective Coatings (LAPC)

LAPC is a specially formulated coating developed by DT Specialty Coatings to safeguard painted surfaces from damage during system processing and transit. The material is applied using a Sames applicator. The LAPC dries in as little as 30 minutes, offering fast and effective protection. Ideal for bumper parts, closure panels, and vehicle bodies, it’s a reliable solution for maintaining surface integrity throughout production and shipping.

- Ensures complete sealing to prevent ingress of contaminants during transit.

- Validates consistent gaps to maintain structural integrity and aesthetics.

- Delivers precise and reliable sealing in hard-to-reach areas.

Ready to improve your process?

Whether you're planning a new system or optimizing an existing one, our team can help you design the right automation solution for your production goals.