TURNKEY AUTOMATED SYSTEMS

Robotic Sealing Applications

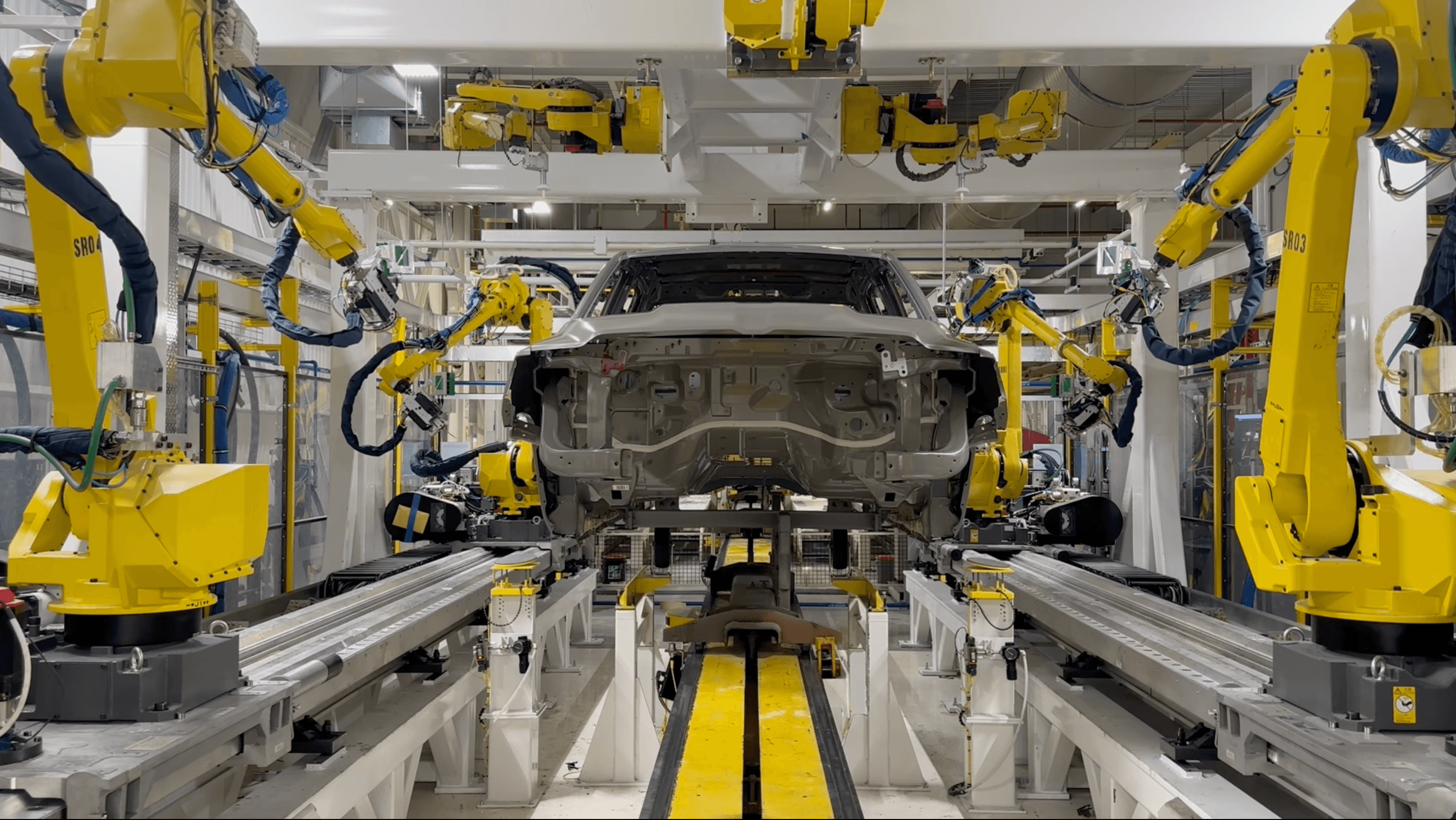

Encore Automation is revolutionizing precision and efficiency in robotic sealing applications. With our advanced automation technologies, we ensure accurate and consistent sealant application, enhancing product durability, safety, and performance. Our solutions empower manufacturers to boost productivity and uphold the highest quality standards, meeting the evolving demands of modern industries.

Hem Flange Sealing

Encore has integrated automated hem flange sealing across all closure panels, leveraging advanced vision technology for gap validation, tool verification, and tip cleaning. This ensures a precise and consistent bead on every seam, enhancing sealer bead appearance and hem flange coverage. Additionally, it helps reduce manual labor, training costs, and downtime, providing a significant operational advantage.

- Automated sealing process ensures precise and uniform application, enhancing durability, weather resistance, and overall structural integrity.

- Advanced sealing technology provides consistent and reliable application in concealed areas, improving adhesion and long-term performance.

- High-precision vision guidance system enables accurate positioning and alignment, optimizing automation efficiency and reducing errors in assembly processes.

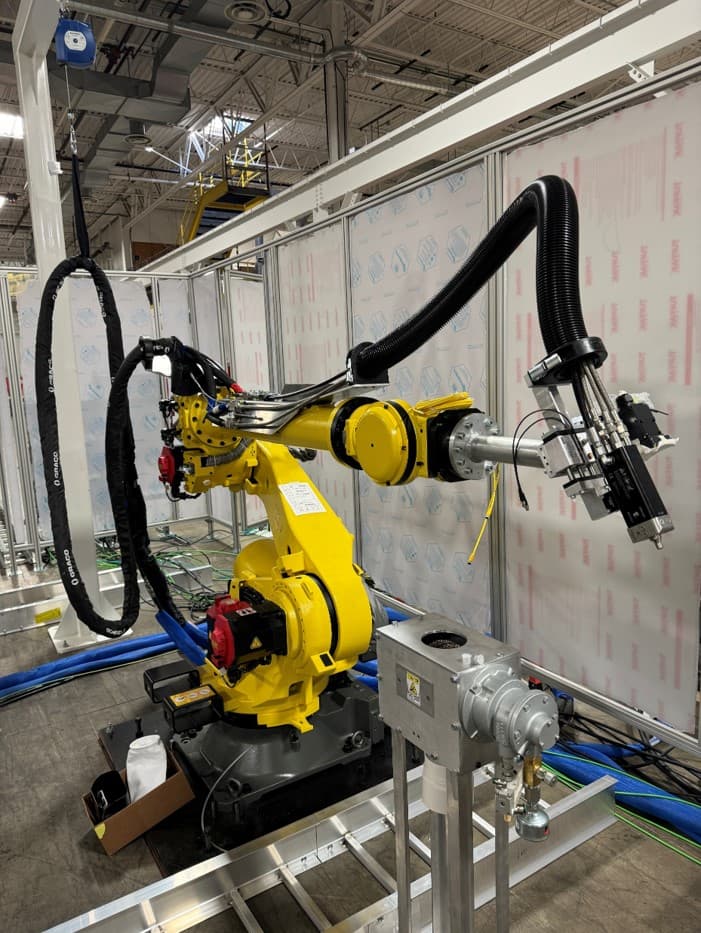

Robotic Skiving

Encore offers innovative solutions for robotic skiving. Our robotic skiving tool can function as a standalone unit or be mounted alongside existing sealer guns. Designed with a retractable mechanism, it extends and retracts as needed, ensuring seamless integration without interfering with sealing operations while reaching difficult-to-access areas. This tool is highly effective for smoothing sealer on windshield flanges, tail lamp areas, and other critical body points where part clearance is essential.

- Advanced automation enhances process consistency while minimizing the need for manual labor, ensuring efficient and repeatable operations.

- Precision-driven automation optimizes application accuracy, reducing defects and enhancing overall product quality and reliability.

- Innovative retractable skive design enables precise application in confined or complex areas, improving coverage and operational flexibility.

Sealer Applications

Encore brings extensive expertise in integrating turnkey automation solutions for liquid-applied sound deadener, underbody coatings, and PVC sealing for exterior, interior, and underbody applications. We conduct high-quality modular builds at our facility, allowing your team to fully validate all systems before field installation. Our modular builds feature full-scale cells equipped with powered robots, ghosting capabilities, rails, robot controllers, filter stands, ISDs, and safety fencing with operational safety gates. During this process, we meticulously validate robot pathing, safety systems, and any known issues to ensure a seamless and efficient installation in the field.

- Automated robotic systems ensure precise and uniform interior seam sealing, enhancing durability, water resistance, and overall structural integrity.

- High-efficiency robotic application of underbody sealants provides superior protection against corrosion, moisture, and environmental wear.

- Automated robotic coating application delivers consistent underbody protection, improving vehicle longevity and resistance to harsh conditions.

PURFoam

Encore provides turnkey solutions for PURfoam applications. Our team is experienced in integrating automation cells, manual stations, and converting existing manual stations into automation cells. Robotic solutions utilizing the on-arm vision system for part position offsets

- Ensures robust sealing for enhanced durability and performance.

- Applies coatings to reduce vibration and increase protection against corrosion.

- Advanced vision systems ensure accurate and defect-free application.

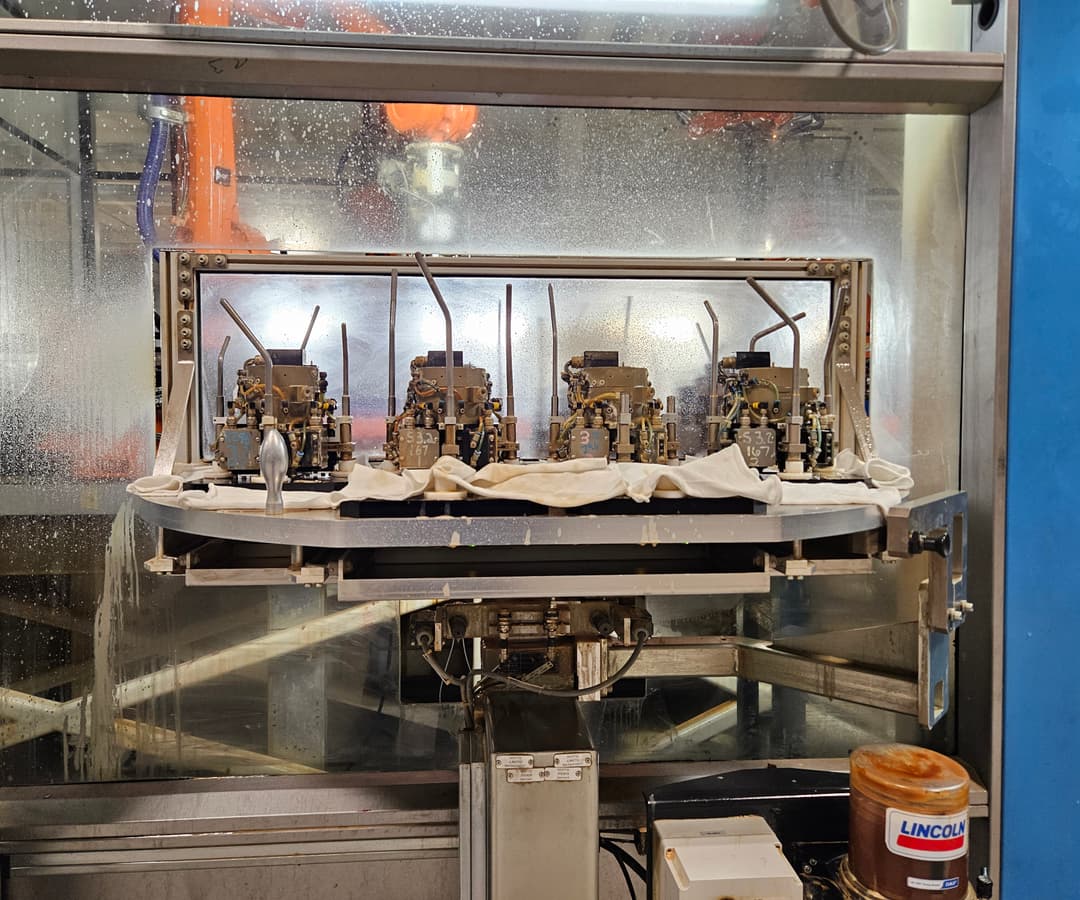

Cavity Wax

Encore Automation specializes in advanced automated cavity wax application technologies designed to deliver consistent corrosion protection to internal vehicle surfaces. Our system utilizes precision robotic application with adaptive nozzles, ensuring full coverage in hard-to-reach areas. Featuring robot-mounted and stationary configurations, the system efficiently applies cavity wax while minimizing material waste through controlled spray patterns and real-time monitoring. The self-cleaning nozzle technology and compact design ensure minimal maintenance and seamless integration into existing production lines. Our automated cavity wax systems enhance corrosion resistance, reduce manual labor, and increase process reliability, offering automotive manufacturers a robust solution for long-lasting vehicle protection.

- Ensures consistent protection in hard-to-reach cavities and tight spaces.

- Guards against rust, moisture, and environmental damage.

- Minimizes material waste and application time with optimized processes.

Ready to improve your process?

Whether you're planning a new system or optimizing an existing one, our team can help you design the right automation solution for your production goals.