TURNKEY AUTOMATED SYSTEMS

Encore Dense Phase Powder Application and Distribution

Encore Automation is renowned for its advanced technology and expertise in dense phase powder distribution and application. Our highly efficient systems minimize capital and operational costs by requiring less automation, shorter booth lengths, and other optimized features detailed below.

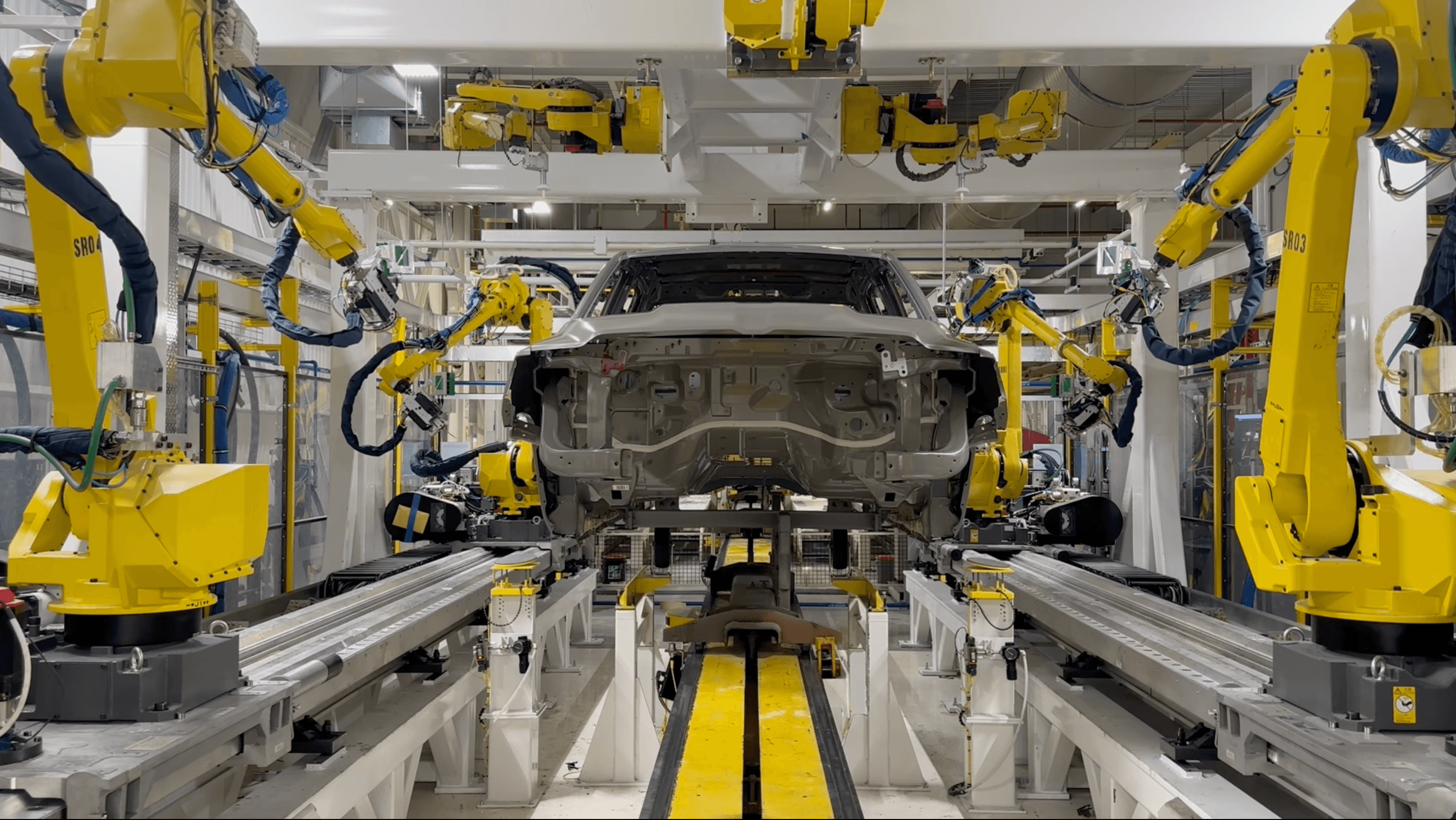

Encore Automation Dense Phase Powder Application

Encore Automation’s innovative dense phase powder application delivers superior coating performance while optimizing efficiency and reducing costs. Our advanced technology ensures powder flows like a liquid, achieving a highly uniform film with improved appearance and quality. The system’s bell-shaped spray pattern provides excellent coverage, with the flexibility to produce narrow patterns for precision cut-ins and wider patterns for larger surface areas. With a high flow capacity of up to 800 grams per minute, it enhances transfer efficiency, minimizes total film build, and reduces defects. Additionally, our rapid 5-second color change capability maximizes productivity by minimizing downtime.

- Optimized powder delivery system enhances transfer efficiency, ensuring uniform coverage while minimizing material waste.

- Advanced system design maximizes efficiency, requiring fewer robots and applicators while maintaining high-quality coating results.

- Compact booth design optimizes space utilization, reducing overall footprint without compromising production capacity.

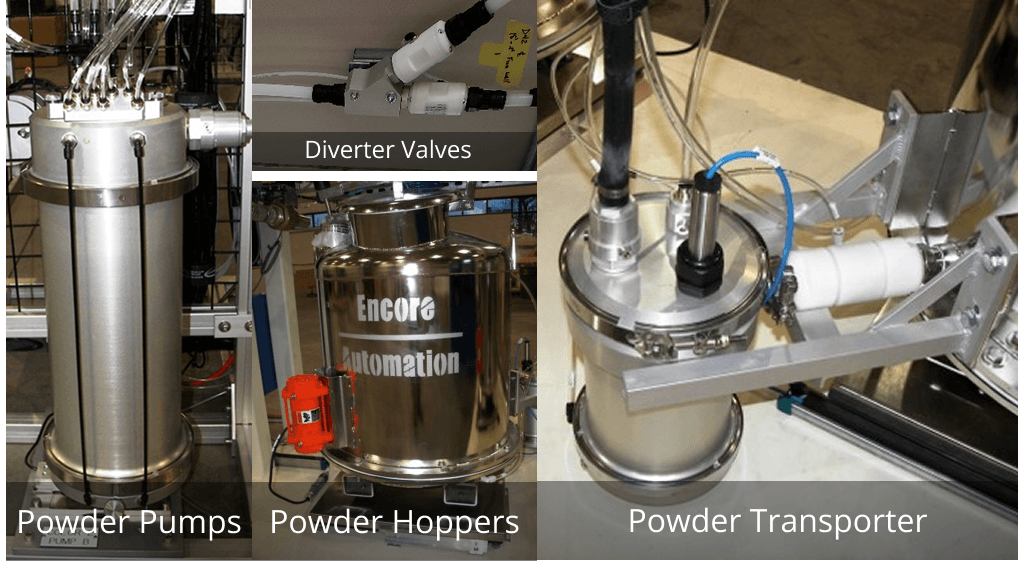

Encore Automation Dense Phase Powder Distribution

Encore’s Dense Phase Distribution System utilizes patented technologies to transfer powder in a fluidized state from the bulk unload pump to the final feed pumps, which then supply the applicators. This process is facilitated through specialized hoppers, pumps, and diverter valves, ensuring efficient and consistent distribution. The system tracks powder usage per cycle utilizing automatic weight controllers and load cell-mounted powder pumps, providing real-time data monitoring by vehicle and applicator. This information is easily accessible via GUI, ensuring precise control, reduced maintenance, and long-term reliability. A reclaim system can be integrated to recover up to 98% of material, significantly reducing waste. Our dense phase pump transfers powder from the collection system beneath the booth to a reclaim hopper and then to a mix hopper, where it is blended with fresh powder for reuse in production.

- Optimized system design lowers initial investment by minimizing equipment requirements while maintaining high-performance coating capabilities.

- Efficient powder distribution reduces energy and material consumption, leading to lower operational costs and improved sustainability.

- Streamlined automation and compact booth design optimize production space, reducing complexity and overall system footprint.

Ready to improve your process?

Whether you're planning a new system or optimizing an existing one, our team can help you design the right automation solution for your production goals.